Our R290 gas boasts high thermodynamic efficiency, making it a superior choice. Its environmentally friendly composition results in reduced greenhouse gas emissions, contributing to a cleaner planet. R290’s non-toxic and non-corrosive characteristics enhance safety during operation and maintenance. By harnessing the power of R290 in our hot water heat pumps, we prioritize energy efficiency and cost-effectiveness.

Energy Efficient

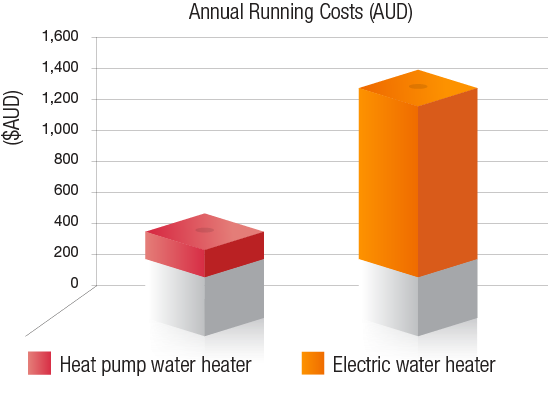

By transferring heat from the air to heat the water, our heat pumps are 5x more energy efficient than traditional electric or gas systems.

Reduced Energy Bills

Greentech energy technology that reduces your household’s carbon footprint and your energy bills by up to 80%.

Easy Installation

No solar panels, inverters, gas lines or canisters are needed. Rain or shine, you can enjoy hot water anytime.

24/7 Hot Water

Manufacturer’s guaranteed warranty. 7 years on the cylinder,5 years on compressor and 2 years on workmanship.

By transferring heat from the air to heat water, a heat pump is 5X more energy efficient than traditional electric or gas systems.

Handy Controller

Providing intuitive operation & helpful functions such as temp setting, timer & safety lock

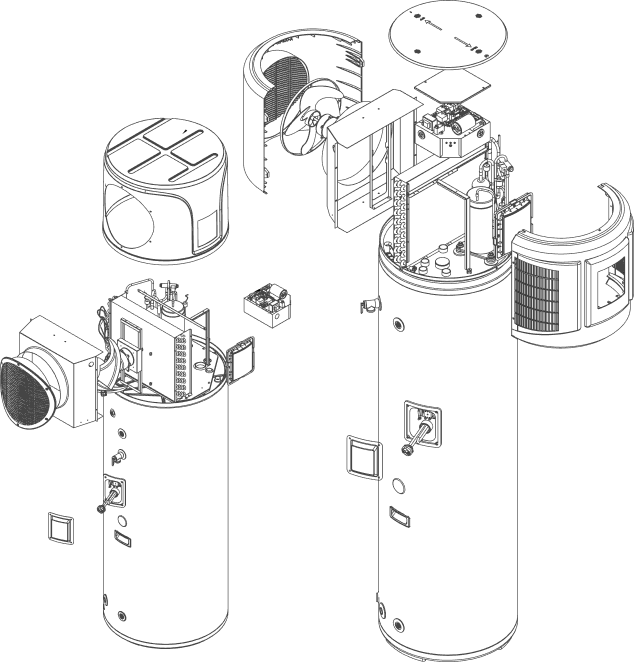

Heat pumps utilise an ingenious technology to efficiently transfer thermal energy directly from the surrounding air and into the water, and so do not rely on direct sun or fossil fuels to provide an energy source.

The compressor pressurises the refrigerant into a hot gas

The hot gas inside the condenser coil heats the water inside the coil-wrapped tank

The refrigerant reverts back to a liquid after heating the water and continues to the evaporator for the process to start again

Hot Water Heat Pump, 300L

Capacity: 300L

Power supply: 220-240V~, 1Ph, 50Hz

Unit dimension (ΦD×H): Φ640×2,010 (mm)

Packing dimension (L×W×H): 750×745×2,210 (mm)

Net / Gross weight: 130 / 144 (kg)

Low pressure protection: Yes

High pressure protection: Yes

Hot Water Inverter Heat Pump, 300L

Capacity: 300L

Power supply: 220-240V~, 50Hz

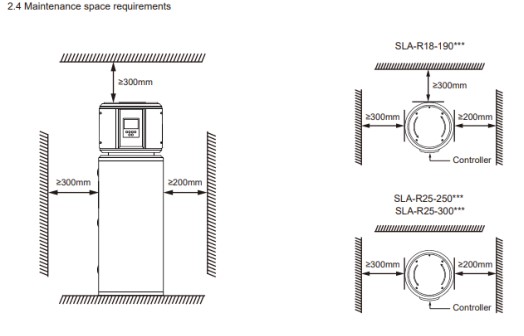

Unit dimension (ΦD×H): Φ650×1897 (mm)

Packing dimension (L×W×H): 750×745×2,210 (mm)

Net / Gross weight: 126 (kg)

Low pressure protection: Yes

High pressure protection: Yes

Hot Water Inverter Heat Pump, 270L

Capacity: 270L

Power supply: 220-240V~, 1Ph, 50Hz

Unit dimension (ΦD×H): Φ640×2,010 (mm)

Packing dimension (L×W×H): 750×745×2,210 (mm)

Net / Gross weight: 130 / 144 (kg)

Low pressure protection: Yes

High pressure protection: Yes

The water coming out of the Condensate Drainage outlet is a part of the heat pump’s usual operation. As moisture from air gets densified on the cold evaporator surface, it forms thousands of water droplets which sometimes create a thin stream of water. Condensate overflow is not coming from the house’s water supply. So, it has no impact on the water bill or energy efficiency. Humid weather makes evaporators form more water droplets.

Condensate water should be discharged through a pipe to a relevant place for water drainage. It should not be stored or collected in buckets.

The running parameter of SLA Heat Pump Water Heater gives various sensor readings which indicate the status of the system. As a part of the remote assessment, SLA may ask to check the Running Parameters to understand if there is any problem with the system. Since these readings are taken from various sensors, the user cannot modify them.

| Model | SLA-R25- 300D/N4D4 | SLA-R25- 300D/N3D4 | SLA-R18- 190D/N3A4 |

|---|---|---|---|

| Heat Pump Mode | 300D/N4D4 | 300D/N3D4 | 465 W |

| Electric Heater Mode | 2000 W | 2000 W | 2000 W |

| Fast Heating Mode | 2480 W | 2610 W | 2465 W |

| Model | SLA310-R290- H25E0 | SLA260-R290- H25E0 | SLA200-R290- H18E0 |

|---|---|---|---|

| Heat Pump Mode | 480 W | 480 W | 350 W |

The normal operating sound pressure level for a heat pump water heater is below 60 dB(A). If the sound/noise pressure level exceeds 60 dB(A), users are encouraged to contact Smart Lifestyle Australia (SLA) with appropriate evidence for further investigation.

The acceptable noise pressure level for SLA heat pumps ranges from 48dB to 58dB, with a tolerable variation of ±2dB.

Sound measuring apps may have a certain amount of measurement error due to factors like environmental noise and air flow. The acceptable noise range in the user manual applies under appropriate conditions, ensuring minimum external noise. For accurate measurements:

SLA heat pump water heaters should not be installed on off-peak meters because they require a constant electricity supply to operate efficiently.

Controlled load/off-peak meter plans allow devices to use power at lower rates during specific times, usually at night or on weekends. Conventional electric hot water systems use a lot of power, so they’re connected to off-peak meters to save costs.

In contrast, a heat pump water heater uses only about 20% of the energy of a conventional system and can achieve over 400% efficiency. Even when connected to the main circuit and left ON all day, it saves electricity.

A heat pump water heater does not actively create water pressure. The main water supply pressure pushes the water through the heat pump’s internal tank towards the house. The system uses a compressor and refrigerant cycle to transfer heat from the surrounding air to the water in the tank. This process heats up the water but does not pump or pressurize it.

At SLA, we’re all about helping homeowners and businesses live smarter, save more, and do their part for the planet. Think of us as your personal energy upgrade team—we make cutting-edge energy solutions that slash your bills and shrink your carbon footprint.

16 Fastline Road Truganina VIC 3029

U1/41 Anzac St, Greenacre NSW 2190

470 Pauls Terrace, Fortitude Valley, Brisbane QLD 4006

1800 951 834